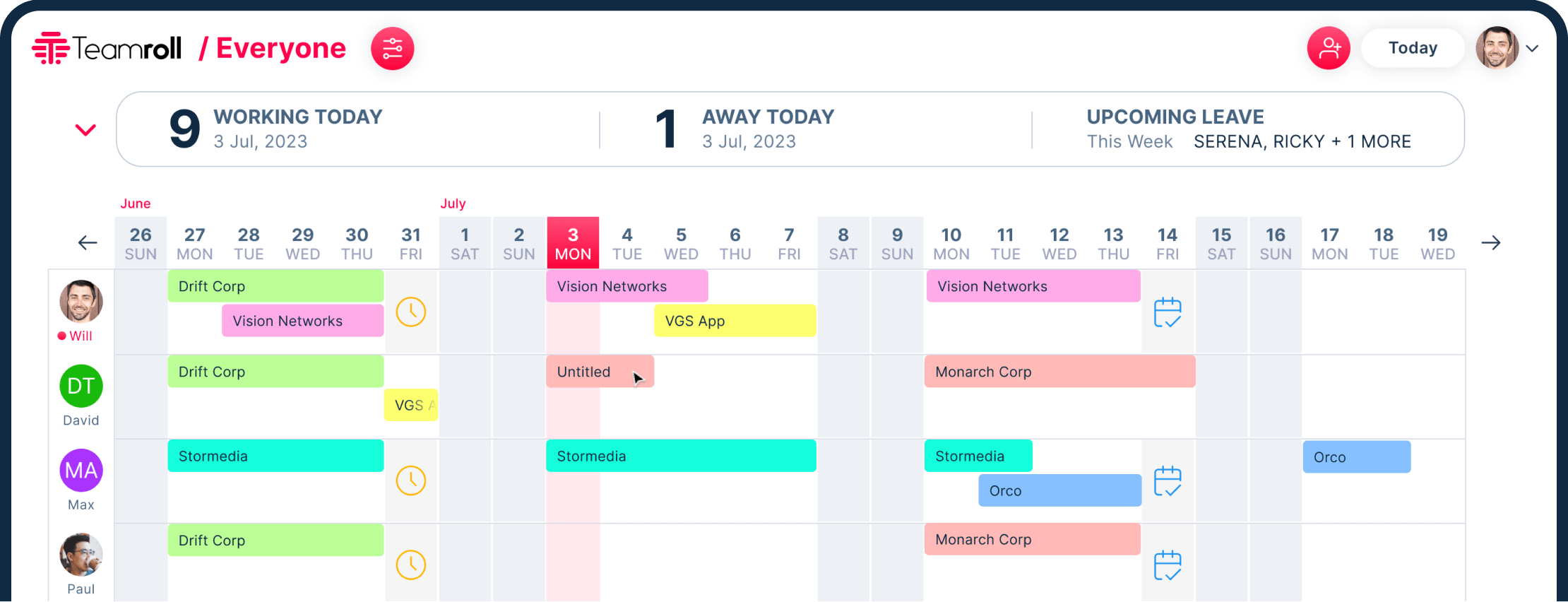

Having run an agency for over ten years, our biggest challenges always seem to boil down to managing our team and juggling the resources we need…

UPS software engineers recognised that left hand turns (the equivalent of right hand turns in Australia and New Zealand) were starting to cause increasingly longer delivery delays for their truck drivers. Drivers sitting idle waiting for a gap to turn, not only wasted time, but increased the likelihood of an accident (causing further delays).

Based on their findings, UPS decided to change their EDD software to heavily favour right hand turns, even if the drivers had to travel longer distance to avoid making left hand turns.

While this was originally done as a policy change for drivers to follow, it was still left to the drivers decision on when to follow the policy or not. Using GPS software, UPS now has every route mapped out, providing right-turn only directions to all drivers unless it’s quicker or easier to proceed with a left-hand turn.

The result? Implementing the algorithm change saved UPS $100m, reducing fuel consumption by over 190,000 litres and reduce their total required fleet by 1,100 trucks.

The crazy thing is these improvements didn’t require a massive outlay of costs. It was simply an update UPS made to existing software.

It’s a great example of how well designed software becomes a lever for your business. Allowing you to achieve massive improvements by making small changes.

“Give me a lever long enough and a fulcrum on which to place it, and I shall move the world.” – Archimedes

How can you use and harness custom software as a lever for your business?

The beauty of building software in an agile manner is not just that you can start using and getting value from the product earlier, but also that you have a platform you can tweak an experiment with and sometimes stumble on massive business improvements from very little extra effort.

The beauty of building software in an agile manner is not just that you can start using and getting value from the product earlier, but also that you have a platform you can tweak an experiment with and sometimes stumble on massive business improvements from very little extra effort.